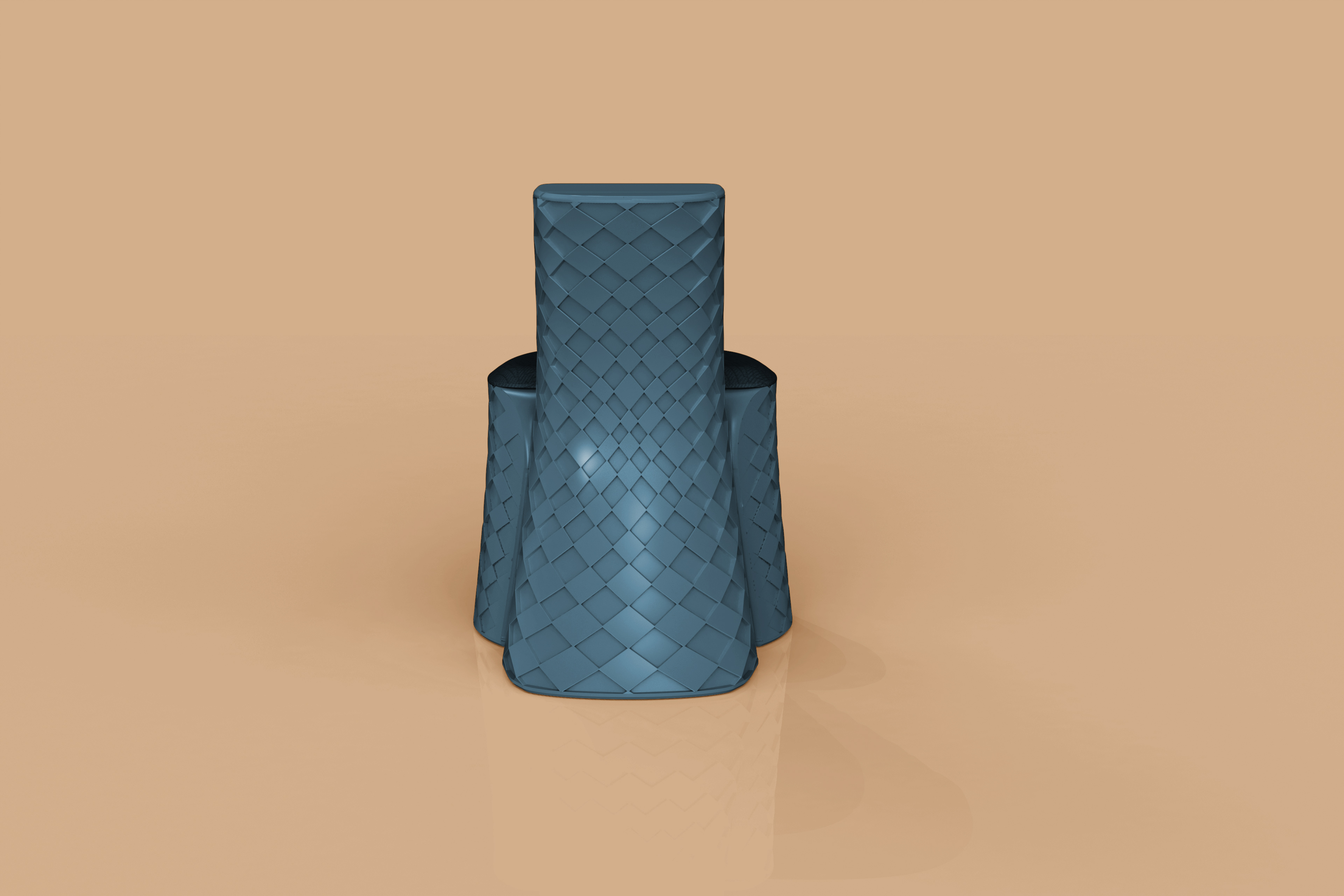

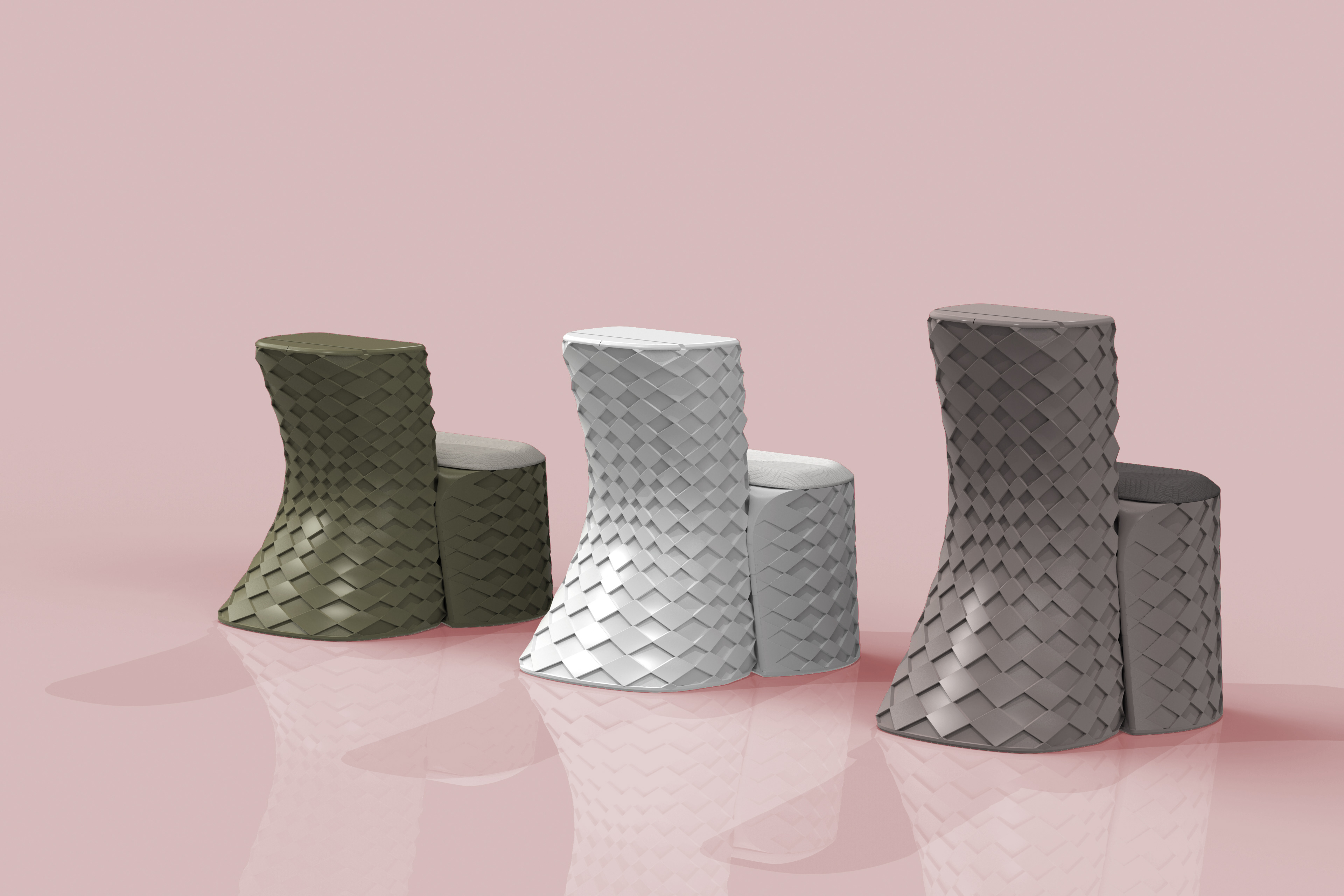

Since the materiality and in particular the manufacturing process here do not match the traditional ones the print process follows new tracks, but strategically this series is taken as a basis and it's implemented advantages and possibilities are used to create both, creative and functional mechanically, sustainable, to represent a new way - an ecological industrial cycle.

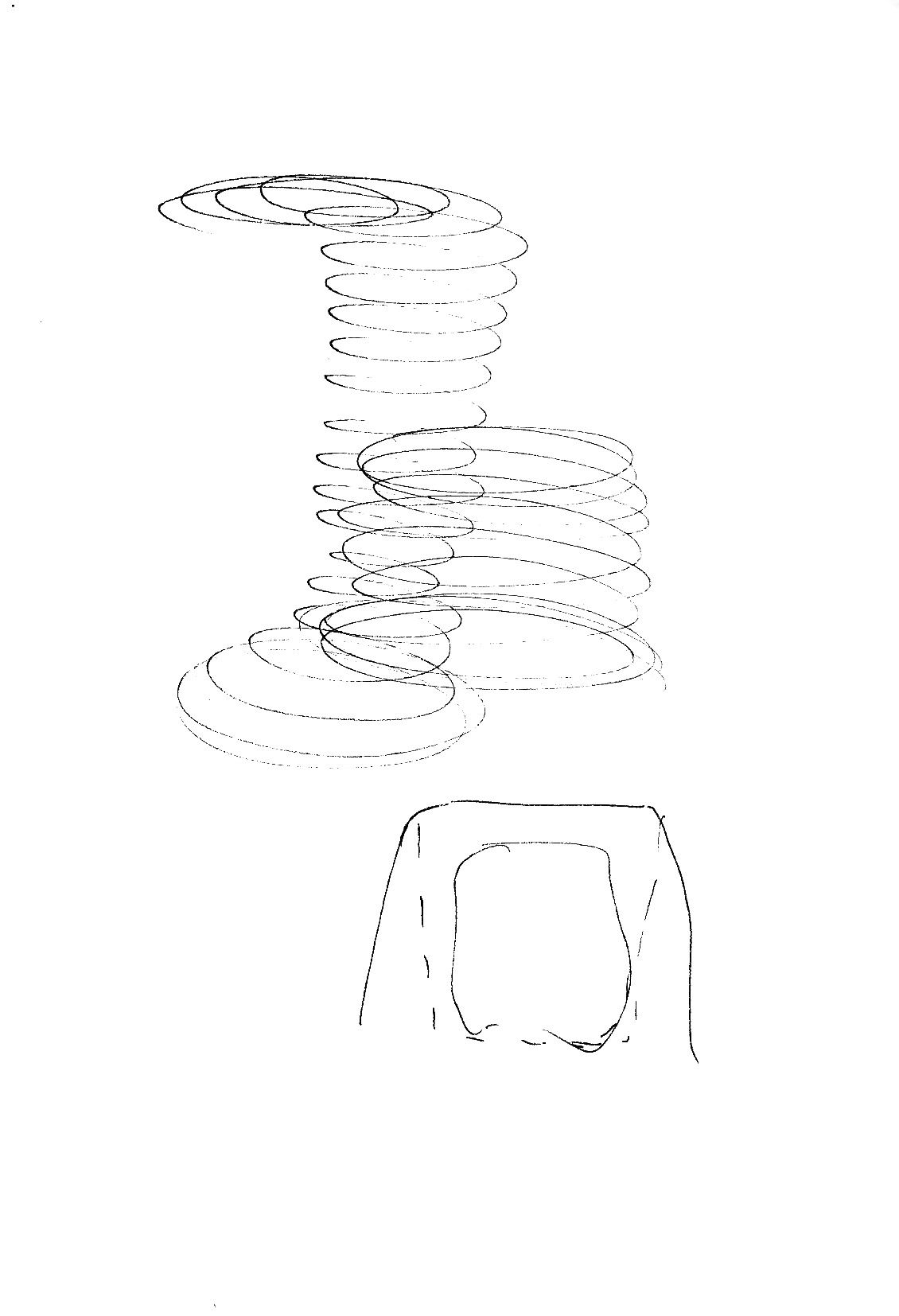

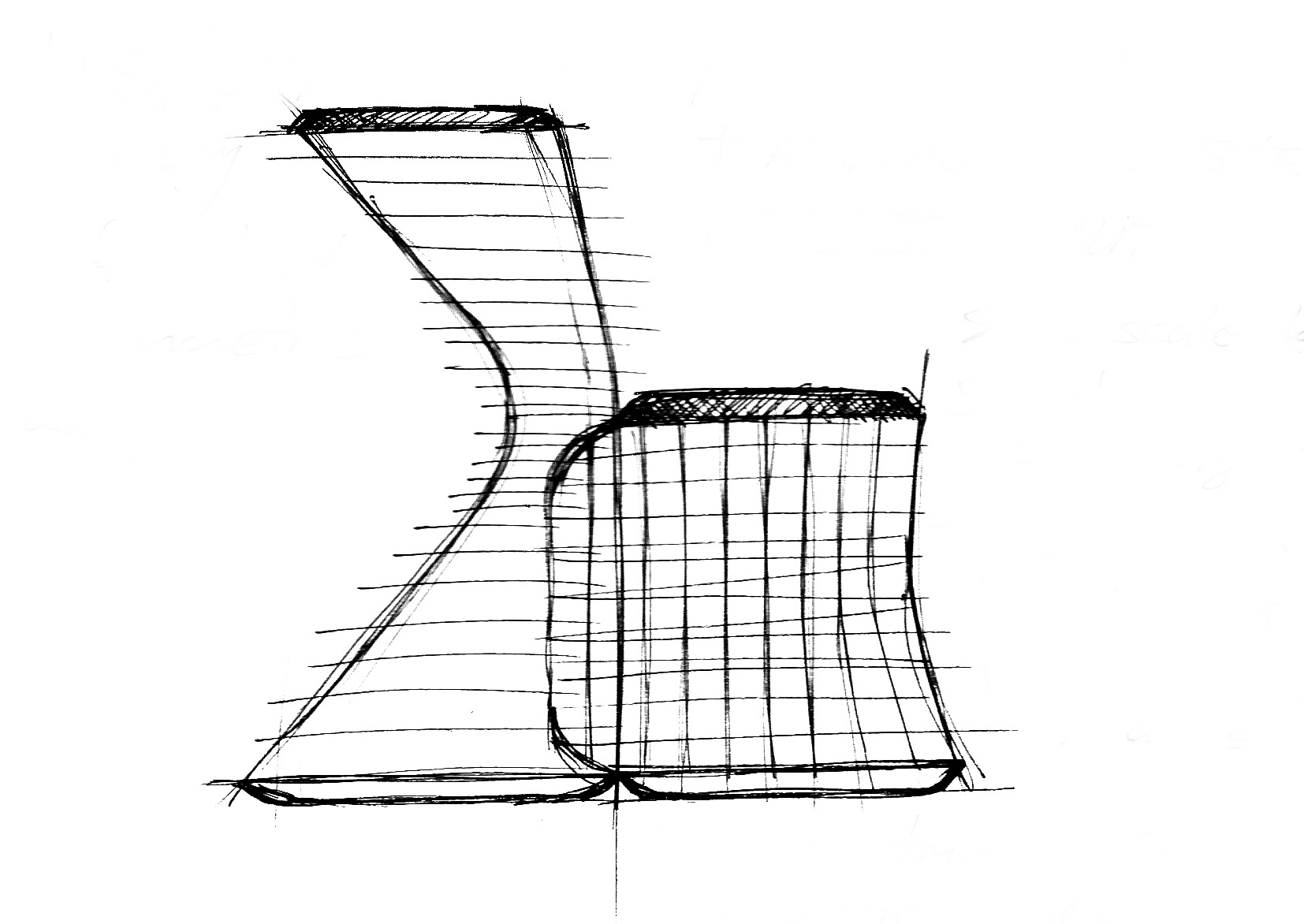

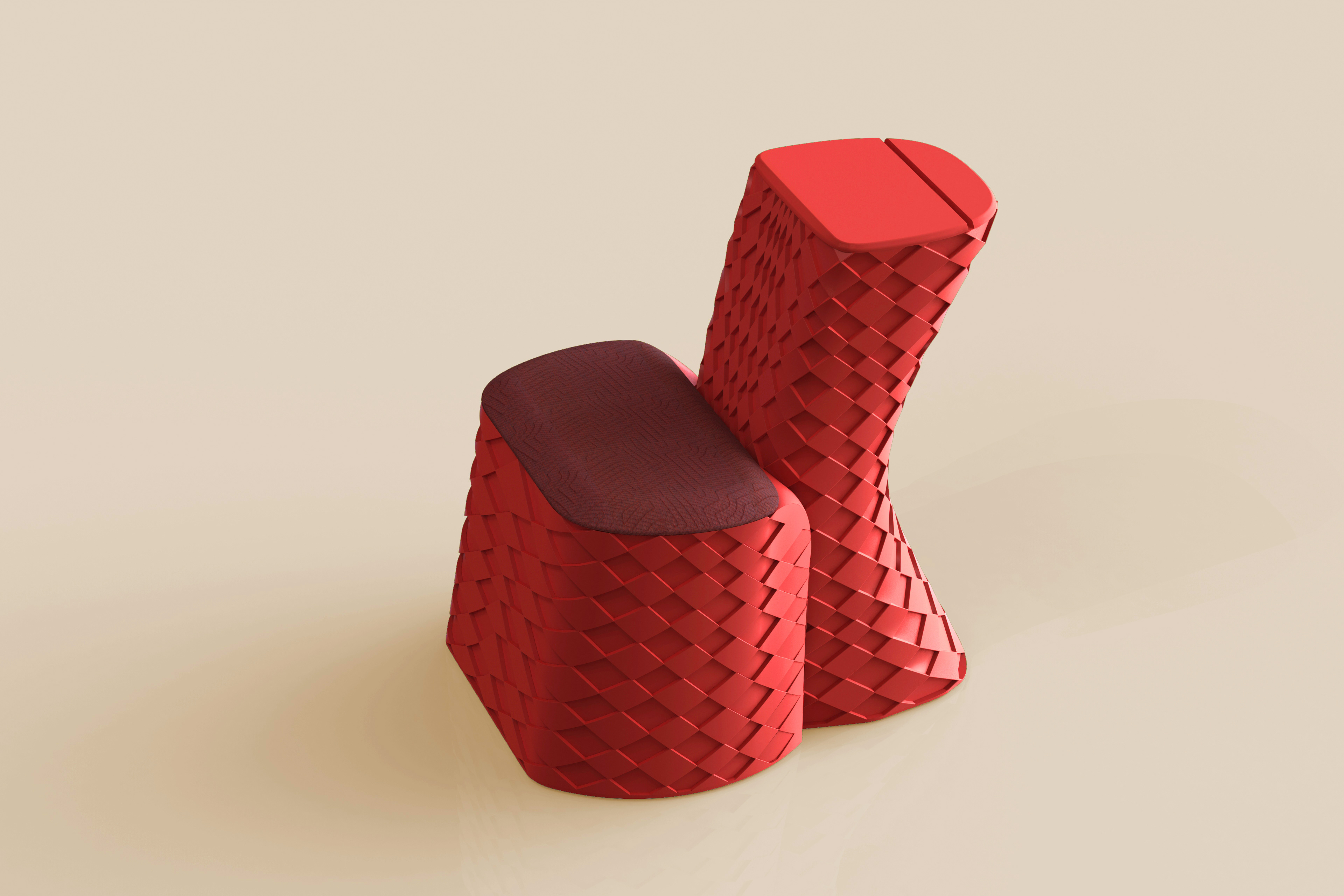

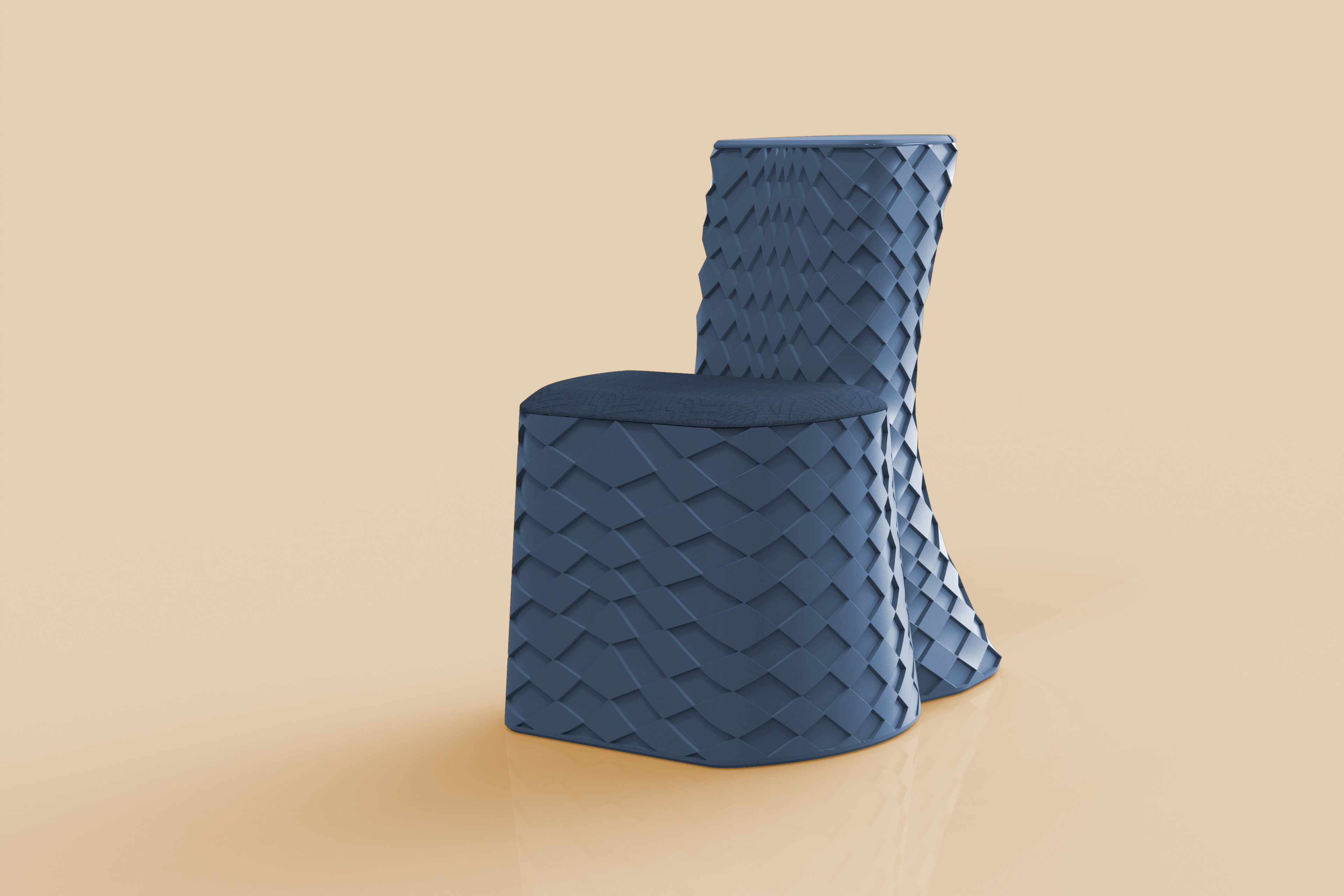

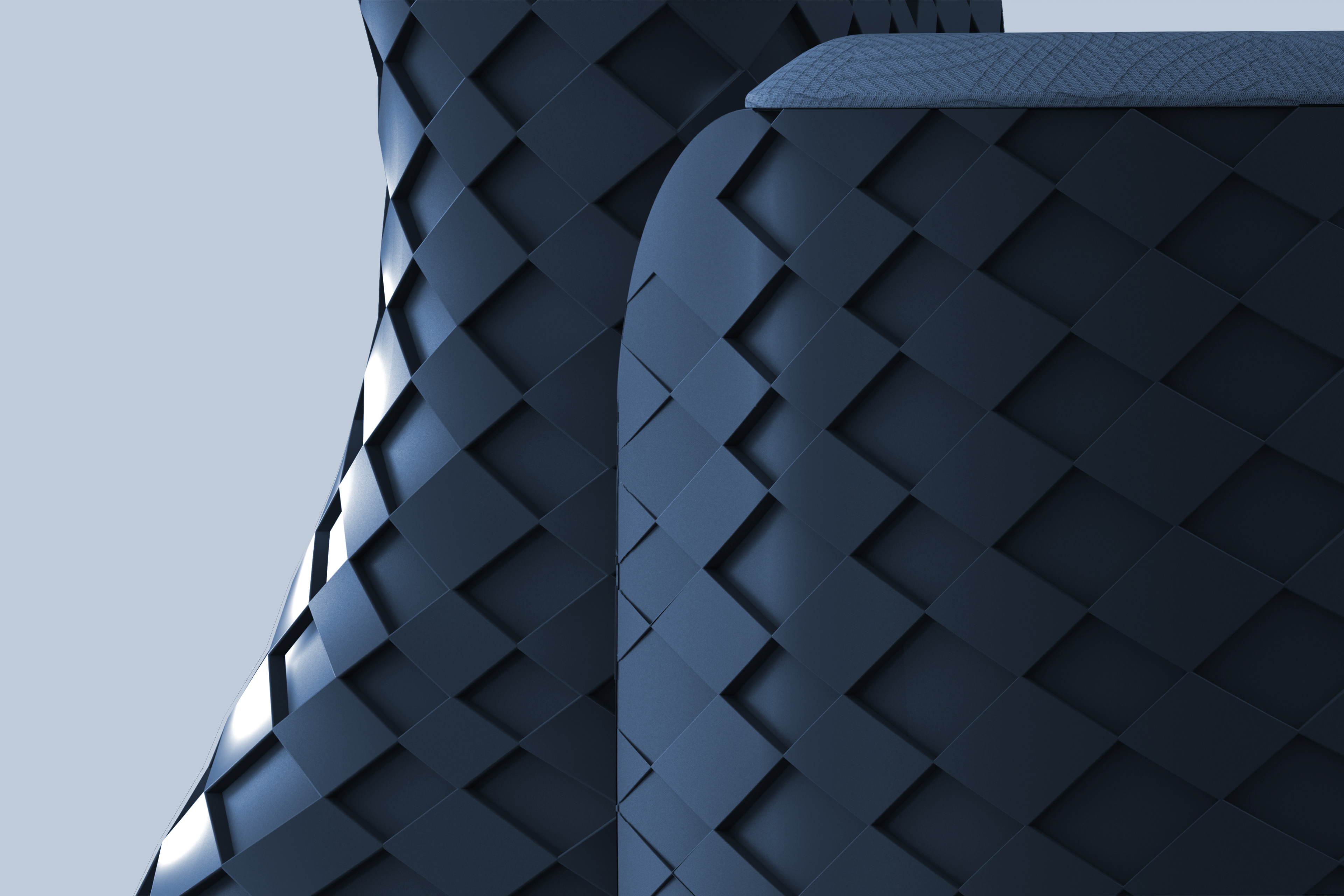

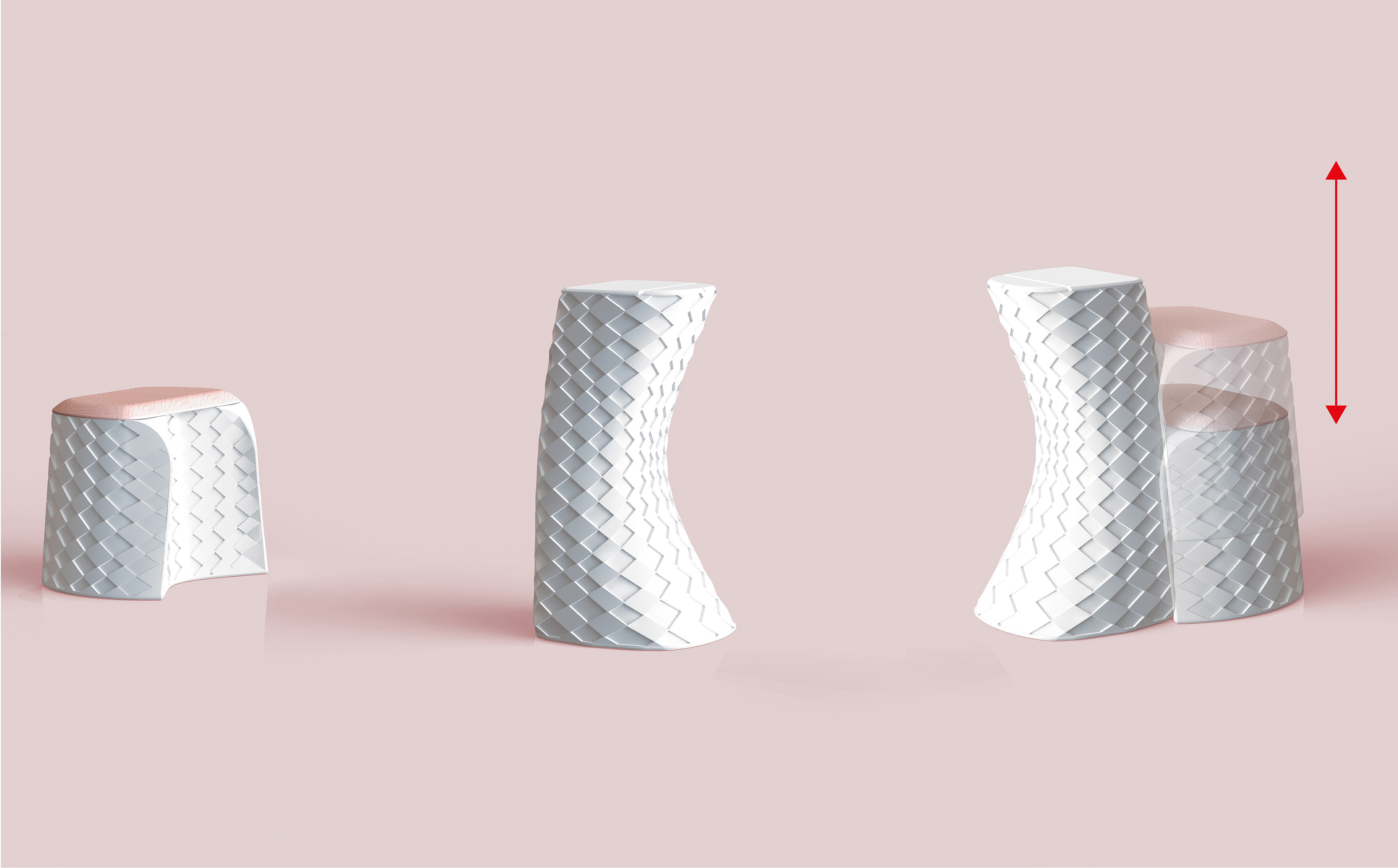

The design first must be adapted to the specifications of the print process, therefore MODE print appears significantly more voluminous than its plastic counterpart - molded process. The walls, on the other hand, can be seen made “unmouldable”, but not only that. A mere texture forgives at this point the possibility with the help of a relevant structure or microstructure, to create an actual sandwich wall. This was successful with the design shown, this microstructure is mechanical a theoretical object, which couldn't mechanically industrial be outlined with the conventional demolding processes.

MODE print by it's production process is fully scaleable.

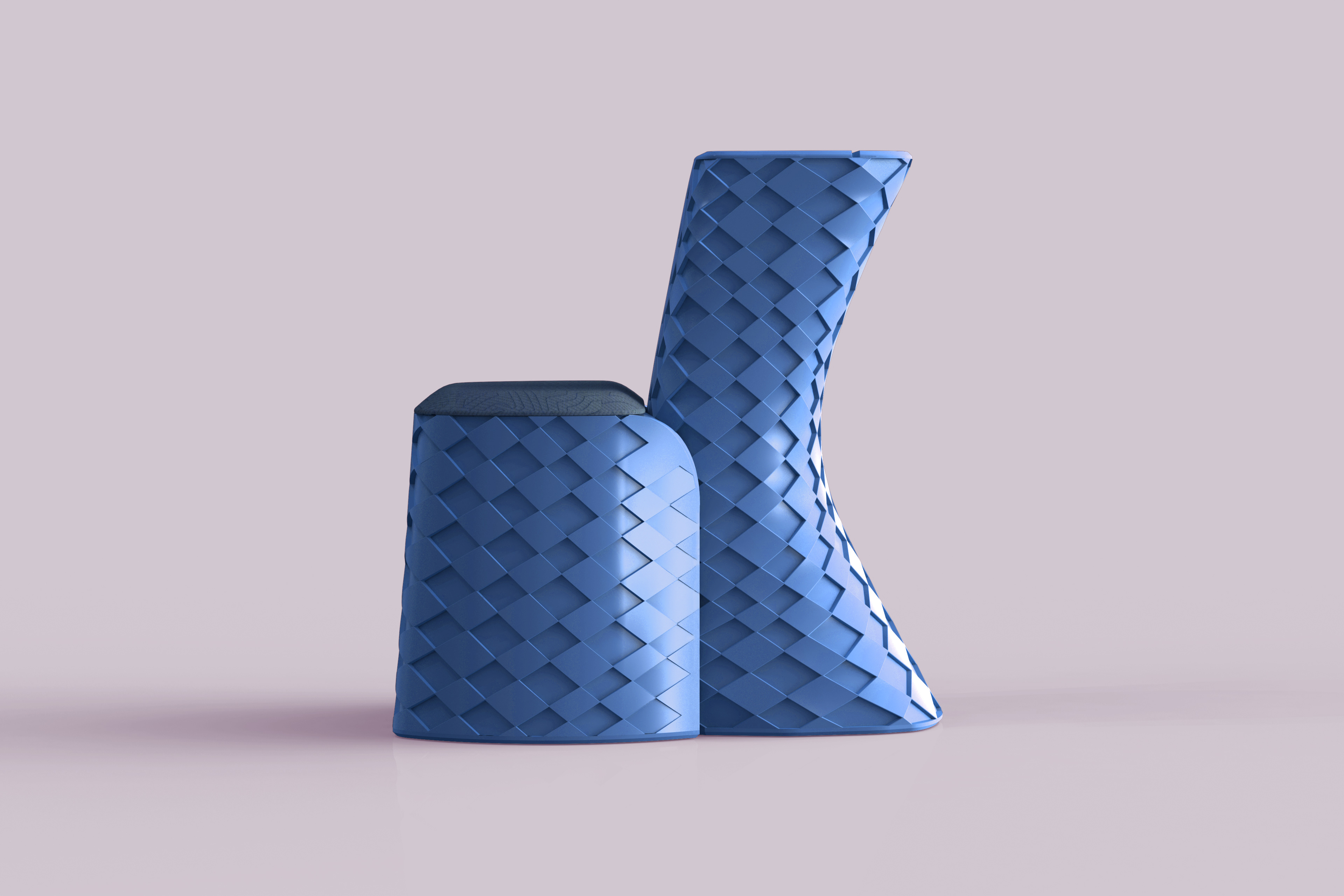

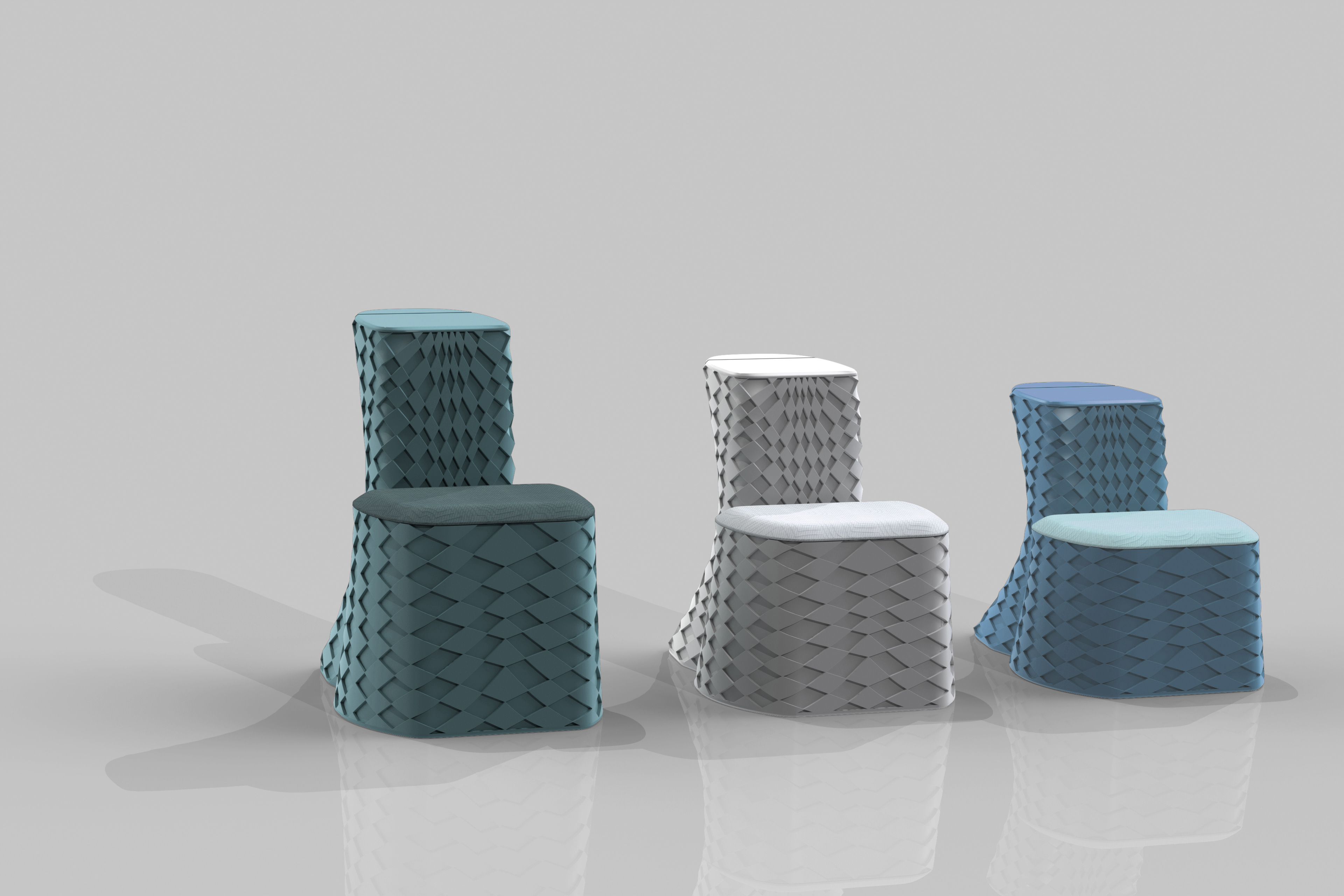

Children and young people in particular have an increased urge to move very simplified access to “agility” or moving learning - MODE print supports exactly this and offers an alternative to traditional approaches to equipping educational institutions and their periphery..... in several neccessary sizes.

The shape, the proportion and the sculptural expression of MODE print leave the propagated clearly recognizeable paradigm shifts, but at the same time it also expresses a sustainable and elegant answer to one of our most interesting demands in the working world - the small, mobile and individual workplace.

The used semi sandwich structure reduces the allover weight to an absolute minimum.

(MODE print was created for WAGNER but not realized)